X32CrMoV3-3 / AISI: H 10

| Chemical Composition (%) | C | Si | Mn | Cr | Mo | V |

| % Average | 0,32 | 0,25 | 0,30 | 2,95 | 2,75 | 0,55 |

| DIN Analysis | 0,28-0,35 | 0,1-0,40 | 0,15-0,45 | 2,70-3,20 | 2,50-3,00 | 0,40-0,70 |

| Thermal Conductivity ( W/ m.K ) | 20°C | 350°C | 700°C |

| 31,4 | 32,0 | 29,3 |

| HEAT TREATMENT | |||

| Tempature(°C) | Time (Hour) | Cooling Environment | |

| Soft Annealing | 760-780 | 2-5* | Furnace |

| Stress Relief Annealing | 600-650 | 2* | Furnace |

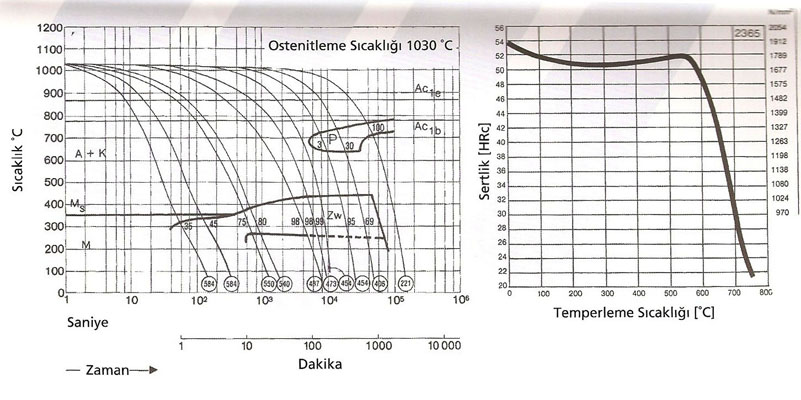

| Hardening | 1020-1050 | - | Air, Oil, Hot bath 500-550°C |

| Tempering | 540-700 | 1 hour for every 20 mm | Air |

Have you reviewed our catalog?

You can see our product range and services in detail in our catalog.

Türkçe

Türkçe