Areas of Use : Tenasteel, which is a part of the cold work tool steel group, shows a feature between powder metal materials with 1.2379 when mold performance is considered. Some properties of Tenasteel steel are as follows.

- Providing high toughness without reducing wear resistance

- Compressive strength better than 1.2379 material under similar conditions

- Easy workability

- Increase mold life

- Achieving high hardness in heat treatment

- Suitability for coating

- Increasing mold and machine efficiency

- Reducing maintenance costs

| Chemical Composition (%) | C | S max | Mn | Cr | Mo | V | Other |

| % Average | 1,00 | 0,005 | 0,35 | 7,50 | 2,60 | 0,30 | Ti |

| Thermal Conductivity ( W/ m.K ) | 20°C | 100°C | 200°C | 300°C | 400°C |

| 21,0 | 10,2 | 11,3 | 11,9 | 12,8 |

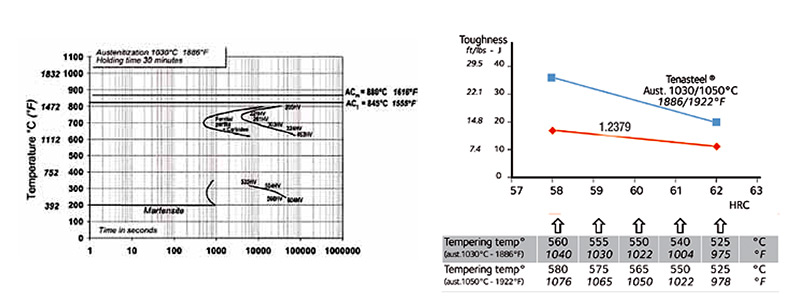

| Delivery Hardness | Austenitizing Temperature | Meaning Temperature | Hardness after Heat Treatment | Toughness Comparison | |

| TENASTEEL® | 1.2379 | ||||

| ≤ 255 HB | 1050 °C | 525 °C 550 °C 575 °C |

60/62 HRC 59/61 HRC 58/60 HRC |

20 J 30 J 35 J |

12 J 15 J 19 J |

Have you reviewed our catalog?

You can see our product range and services in detail in our catalog.

Türkçe

Türkçe